As it stands, conventional meat processors are ‘squeezed’ on price. On one side, the major slaughterhouses want higher prices for their cuts, and on the other, supermarkets ‘don’t want to grant better prices’.

“This is a really big problem,” according to German entrepreneur Laura Gertenbach. And she speaks from experience: Gertenbach comes from a family of farmers and has founded her own organic meat business.

But what if meat producers could work independently of slaughterhouses, and create their own raw material in-house?

Gertenbach believes they can, and together with co-founder and CTO Patrick Nonnenmacher, is developing technology to help them get there. “We want to break the reliance on agriculture and give food producers the opportunity to produce clean meat in their own factories.”

Innocent Meat

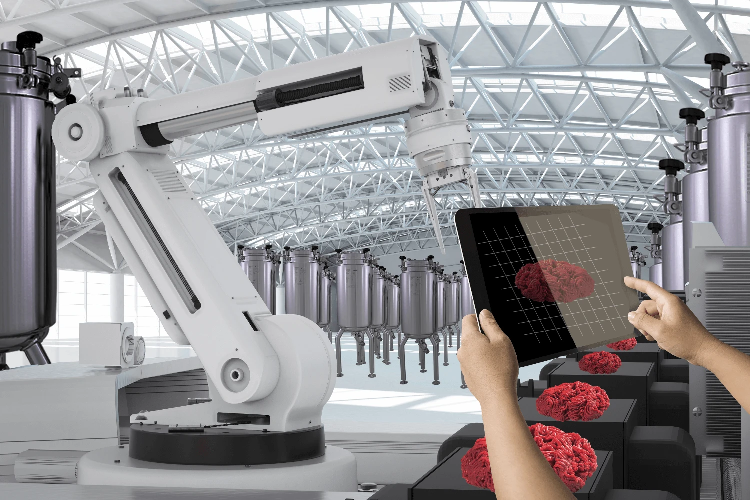

The duo’s start-up, Innocent Meat, is making an automated, end-to-end clean meat production system for the sector. We are essentially offering ‘clean meat as a service’, explained CEO Gertenbach.

Innocent Meat provides meat producers with bioreactors, cell media and growth factors, and access to smart software based on artificial intelligence. Customers needn’t hire scientists nor software developers: “They just harvest the meat and that’s it.”

The initial focus is on cultivated pork production, and in particular, minced pork. “Minced meat is the most produced meat and processed meat in Europe,” explained the CEO. Producers will be able sell cultivated minced pork as is, or process it into sausages and burgers.

In the long-term, the plug-and-play solution will not be limited to pork. To produce another meat, one would need to alter the cell line, but the bioprocess would stay the same. “They can produce any type of meat they want to produce,” she told this publication. “But we are starting with minced pork.”

Keeping the cost down

Across the lab-grown meat sector, pricing is a challenge – largely due to the most expensive ingredient in its production: the proteins known as growth factors.

Innocent Meat estimates that 90% of the cost of cell-based meat is attributed to growth factors. Gertenbach puts this largely down to scale. “Growth factors are [traditionally] a medical product. And the medical industry doesn’t need growth factors in as high volumes as the meat industry,” she explained.

To bring down costs, Innocent Meat is developing its own plant-based growth factors. While the CEO did not reveal which plant proteins it is using in the media, she could reveal that scaling crop production for this purpose would be relatively simple given her agricultural connections. “It would be very easy to plant those crops, scale it, and harvest it,” she reiterated.

Costs can also be brought down thanks to a filtering process Innocent Meat has developed together with a German engineering company. Essentially, the filter means all cell media needn’t be thrown away after each batch, Gertenbach explained.

The start-up has also developed a proprietary method to produce scaffolds in a ‘very cost-efficient way’, she added.

Both green and clean?

Even if cultured meat can reduce its costs to achieve price parity with its conventional counterpart, question marks remain over its sustainability credentials.

In 2019, a study conducted by Oxford University concluded that if the electricity for cultured meat is generated from fossil fuels, its carbon footprint will be similar to that of conventional meat production.

Innocent Meat’s CEO admitted lab-grown meat’s energy use is a concern. However, for Gertenbach, the responsibility is that of national decisionmakers. “The government is responsible for providing green energy…I think the infrastructure for green energy should be provided by [policymakers],” she told this publication. In any case, concerning environmental sustainability, the CEO sees clean meat as being ‘a step forward’.

Regulatory challenges

Another key challenge facing cultured meat producers is regulation, as neither Europe nor the US have approved lab-grown meat. In fact, only one lab-grown meat product has received regulatory approval so far: Eat Just’s cultivated chicken ingredient in Singapore.

Innocent Meat will need to receive regulatory approval before marketing its plug-and-play solution, but fears the European Food Safety Authority (EFSA) may not be the quickest to react.

“I have my doubts that the European Union will be the one that will handle it fast, because we have seen in the past that [EFSA] is not fast enough. Innovation is also something difficult within the European Union.”

Gertenbach predicts the market to first open up in Asia, followed by the US. While she hopes Europe won’t be too far behind, the CEO did say clean meat companies shouldn’t wait for EU approval to commercialise their products.

In fact, the ‘worst thing’ to do would be to wait around for approval, she emphasised. In the meantime, Innocent Meat will investigate Asian markets and look into selling its growth factors to cultivated meat companies.

Innocent Meat was recently accepted into Big Idea Ventures’ third cohort of alt protein-focused start-ups in New York City. The programme runs for five months.

“So far, I am very satisfied,” said Gertenbach. “It has been amazing. We have been learning a lot, and getting new perspectives on different problems. Although I run a business, you can never learn enough – and the programme is a gateway for us to learn how US investors [work].

“Of course, networking is very important – as is networking with the other start-ups.”